WhatsApp)

WhatsApp)

2013/12/03· Ball Mill for grinding cement, building material, fireproof material, chemical fertilizer Zhao Gloria Loading... Unsubscribe from Zhao Gloria? Cancel Unsubscribe Working... Subscribe Subscribed Unsubscribe 55 Loading...

All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity ...

ball mill ultra hard materials As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of ...

A Ball Mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mined products and other materials. It is widely used in building material, chemical industry, etc. There are two ...

Turning Drum Thing A ball mill is a turning drum, lying on its side. So is a concrete mixer, rock tumbler, bottle polisher, parts polisher, etc. Throw in some ... Vertical raw mill pradeep kumar,SlideShare May 15, 2013· Vertical raw mill ...

Grinding media steel balls, hardened steel media, 2 to 12, This steel grinding media for ball mills, pulverizers and attritors is cold forged and, density and hardness, for crushing and mixing heavy and hard materials Contact

Aegis Technology » High Energy Cryogenic Ball Milling Ball mills use impact with attrition principles for grinding the raw material. Inside the ball mills, various sizes of balls are used and classifying liners are used to...

Suitable for grinding hard material. No pollution for the powder with ceramic cement ball mill. Applied material cement, silicate, building material, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc. . ...

RETSCH ball mills are available as mixer mills as well as planetary ball mills. Mixer Mills grind and homogenize small sample volumes quickly and efficiently by impact and friction. They are suitable for dry, wet and cryogenic grinding ...

Ball Grinding Mill, Ball Mill – IndiaMART – Indian . Some of the products sold by the company in the category Ball Grinding Mill are Ball Mill. Buy . Ball Mill can be used for grinding crystalline material, .

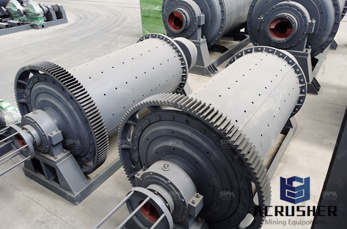

Ball mill, a type of grinding mill, is a cylindershaped device used to grind materials like ores, chemicals, ceramic raw materials and paints. The ball mills are the key milling equipment after material has been crushed. It is divided into ...

Planetary ball mill, Lab soil grinding machine, Laboratory soil grinder Description of Laboratory soil grinder: Every DECO soil powder milling machine is equipped with a round frame sieve. While grinded powder passing through the ...

Xinhai Autogenous Mill Except for few hard ore, most of metal ores could use wet autogenous mill. Simplify the crushing and grinding process; feeding particle size is 200350mm, and after the first autogenous grinding, the product ...

Overview Ideal for large quantities The Planetary Mill FP400 with 4 working stations delivers fast and reliable, due to the particularly highenergy effect of the grinding balls, lossfree grinding results of hard, mediumhard, soft ...

Ball mill A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the ...

ball mill for hard material grinding Grinding Mill . grinding mill for sale: Use the ball mill for the hard . Jul 20, 2013 · LM Series Vertical Mill Performance characteristics. » Learn More ball grinding mill for ceramics | Mobile ...

Horizontal Laboratory Planetary Ball Mill Machine 1 Description Applications Planetary ball mill is the requisite equipment for mixing, fine grinding, small sample preparing, new product development and small volume hightech ...

2016/03/27· A ball mill is a grinding device that is used to turn material into fine powder. Ball mills are cylindrical in shape, and are often the grinder of choice when it comes to mashing paints, ores, ceramic materials, and certain hard ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ...

めまれている· Basic Grinding Mill Design These grinding mills are built in three basic designs: the Overflow, the Diaphragm and the Peripheral Discharge mill. Ball mills are built in Overflow and Diaphragm types. In the Overflow mill the material is ...

Please note: For this DECO mill, you require two or four grinding jars of your choice and the corresponding number of grinding balls. The grinding jar material must also be harder than the material to be ground. In normal cases ...

Specialist Mining Equipment Design and Manufacture Maintenance shutdowns cost real money. In mineral concentrators, grinding mill relining defines maintenance shutdown duration. In other words, mill relining is... Russell Mineral ...

Ball Mills Manufacturer Ball Mill Working Principle A ball mill is a type of grinding mill, it is an aggregate for grinding and crushing (grinder) of hard materials that has the same goal as other grinding machinery and crushing machinery.

Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits. According to the need of customers, ball mill can be either wet or dry designs. Ball mills have been designed ...

WhatsApp)

WhatsApp)