WhatsApp)

WhatsApp)

Search Bid on Equipment Material Handling; Material Testing Equipment; Meat Equipment; Metal Detectors; at Bid on Equipment is the market leader for the online sale Get Price Online roll mill for nonwoven ...

Suranaree University of Technology JanMar 2007 Typical arrangement of rollers for rolling mills Twohigh mill, pullover Twohigh mill, reversing Threehigh mill Fourhigh mill Cluster mill or Sendzimir mill The stock is returned to the

The invention relates to a method for grinding mill material and to a roller mill and is suited in particular to a finest grinding of relatively hard and dry materials, for example cement clinker and granulated blast furnace slag and also for ...

The Hot Rolling Process The primary function of the Hot Strip Mill is to reheat semifinished steel slabs of steel nearly to their melting point, then roll them thinner and longer through 12 successive rolling mill stands driven by motors ...

Processing Approach and Method In broader terms, mineral processing consists of two functions. Firstly, ... which forms a material bed that traps heavy particles and creates turbulence. This turbulence causes heavy particles ...

NIPPON STEEL TECHNICAL REPORT No. 96 July 2007 21 UDC 621 . 771 . 25 Making to High Performance and Productivity Improvement of Steel Bar and Wire Rod Rolling Process Ryuichi SEKI*1 Koichi HASEGAWA*1 Kenji ...

United States Patent US Note: If you have problems viewing the PDF, please make sure you have the latest version of Adobe Acrobat. [ PDF help] Back to full text

Steel Glossary PT American Iron and Steel Institute These include the slabbing mill, hot roll mills, cold roll mills, SR mills, and DR mills. Ferrous (ironcontaining) material that generally is remelted and recast into new is generated ...

The shell made of metal material such as bronze stainless steel is covered with rubber or a synthetic material. Both shell and cover are drilled throughout the surface. A stationary suction box is fitted in the core of the suction roll ...

COLD PILGER MILL ROLL STAND BED SLIDE PLATE HAVING EXCELLENT WEAR RESISTANCE AND ITS PRODUCTION METHOD に にれたコールドピルガーミルロールスタンドベッドスライドおよびその ...

Intelligent Mill (NIM); NIM is a new concept rolling mill which can estimate and control roll force distribution across the width acting between the work roll (WR) and the rolled material. For zero adjustment procedure of individual ...

Two of the most important criteria to consider are the material''s hardness and the finished material''s required particle size distribution. If you plan to use a mechanical impact mill for size reducing particles with a median particle size ...

dryer, with the addition of spray nozzles, fluid bed systems quickly developed into granulators. The introduction of Wurster bottom spray technology enabled extremely effective coating. As a result of the rotor technology, the fluid ...

1981/09/29· I claim: 1. An improvement in a method of rolling steel sheet profiles of different crosssectional shape in universal beam rolling mill trains wherein starting material is rolled in a twohigh reversing ingot rolling mill, in a two ...

pigment testing method for dispersion with two roll mill pigment testing method for dispersion with two roll mill. Posts Related to pigment testing method for dispersion is ideal machine for grinding ...

2017/08/17· rolling mill: see steel steel, alloy of iron, carbon, and small proportions of other elements. Iron contains impurities in the form of silicon, phosphorus, sulfur, and manganese; steelmaking involves the removal of these ...

CNC Bed Mill INSTRUCTIONS HOW TO USE A MILLING MACHINE This webpage is best printed in Landscape format. This information was originally compiled by the US Army. Presented to you free by American ...

no. of layers forming the bed quantity of material per bed quantity of material per layer blending bed capacity method of reclaiming Quantity of material per reclaimer slice All the preblending systems achieve the ...

By this the material bed is compacted to a solid volume portion of more than 80%. The roller press has a certain similarity to roller crushers and roller presses for the compacting of powders, but purpose, construction and operation ...

Billet Mill Round Billet Finishing Line Layout and outline of expansion Billets are the base material for the Wire Rod and Bar Mill. JFE Steel produces two billet cross sections, a 175 mm dia. billet, which receiveslet Mill ...

Determination of the nip zone angle in highpressure grinding rolls 245 The crushing process in the HPGR crushing chamber is evoked by the pressing force from two rotating rollers. The ore is chokefed and the material is dragged ...

ASTM develops technical standards for industry worldwide.

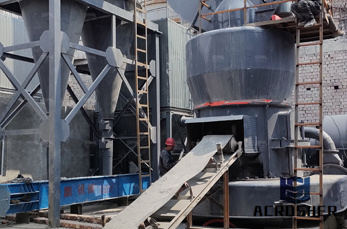

2014/08/05· Method for treating particles of a bulk material and method for controlling a roll mill US * 23. Jan. 1992 6. Aug. 1996 F. L. Co. A/S roller press US * 1. Juni 1995 28. Jan. 1997 Acrowood Corporation * ...

2011/02/01· Optimizing mill performance Feb. 1, 2011 by Mark Fowler Share This: Optimizing a milling system can have different meanings for different people. To some, optimal performance may mean maximizing extraction or maximizing ...

WhatsApp)

WhatsApp)